Our Sand Muller machine showcases our robust production capacity, ensuring timely fulfillment of customer demands. Essential for sand mold creation, it expertly mixes and binds sand, water, clay, and occasionally chemicals, guaranteeing optimal sand preparation for casting processes. At Fusion Equipment, quality and efficiency are our priorities.

With the capability to melt 10 to 15 tons of metal daily, our casting foundry is a cornerstone of our production prowess. We specialize in crafting a diverse range of products including Dumbbells, Weight Plates, Other Machinery, and Industrial Castings, with a portfolio boasting over 500 unique items. Our meticulous molding process ensures precision and quality in every piece.

With a capacity of 250 kg, our shot blasting machine plays a crucial role in our production line. This process effectively removes dust and burrs from dumbbells and weight plates, ensuring a clean surface before moving on to the next stage of processing.

Grinding, a friction-based process, serves to eliminate excess metal from workpieces, effectively addressing issues like hard burrs and chip removal through abrasive action. As a subset of cutting, grinding involves the precise removal of material, making it a true cutting process essential for achieving the desired shape and finish of the final product.

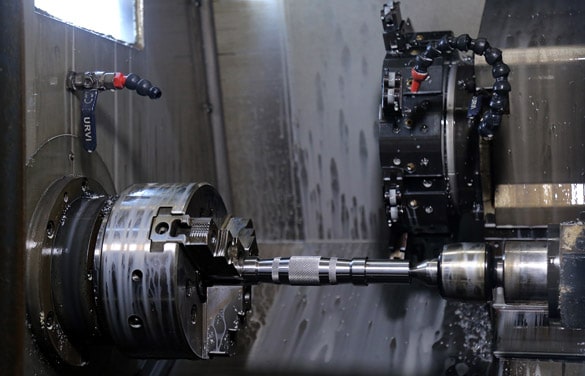

The knurling process is a masterpiece, especially when applied to the outer diameter of gym equipment handles. Diamond knurling, specifically tailored for gym equipment, not only enhances the aesthetics but also significantly improves grip and functionality. Our team meticulously executes diamond knurling, ensuring precision and durability that withstands the test of time, ultimately providing users with a comfortable and secure grip for effective weightlifting.

With three MIG welding machines at our disposal, welding plays an integral role in the manufacturing process of gym equipment, providing the finishing touches and final shaping. Our highly experienced welding machine operators ensure precise and durable welds, crucial for creating unbreakable joints, especially in the handlebars of dumbbells. These welded joints guarantee a long lifespan, offering gym enthusiasts reliable equipment for sustained workouts.

Our natural rubber molding process begins with meticulous preparation in our in-house rubber mixing machine. We take great care to ensure the quality and integrity of the rubber, meticulously measuring and blending various powders and chemicals to achieve the desired strength and durability. This commitment to quality enables us to deliver the best possible products to our customers, ensuring their satisfaction and trust in our brand.

With molding machines dedicated to crafting dumbbells, our rubber molding process is essential for enhancing both the functionality and durability of our gym equipment. Through a combination of pressure and heat, we meticulously mold natural rubber onto the castings, ensuring optimal elasticity and sustainability. Maintaining quality throughout the molding process is paramount to us, whether it's casting or molding. Moreover, our flexible production capacity allows us to meet the varying demands of our customers without compromise.

The label-making process is a meticulous art form at our facility, where every detail matters. Our experienced team understands the importance of customer input and meticulously incorporates their ideas into the label design process. From logo placement to size and color combination, we ensure precision and accuracy to bring our customers' visions to life on rubber labels. As an OEM supplier, our goal is to make custom logo dumbbells and weight plates not only functional but also visually appealing, enhancing our customers' brand image. Ultimately, we believe that our customers' reputation reflects our own, driving us to deliver excellence in every aspect of our service.

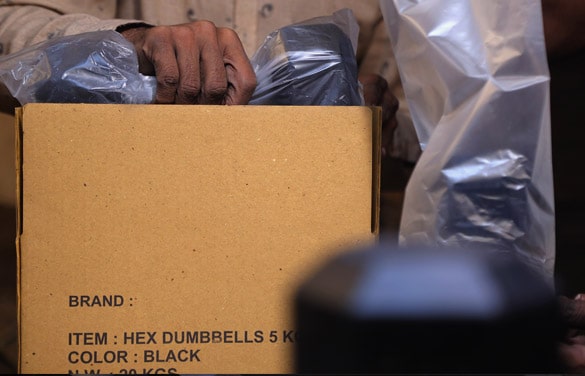

Good packing is essential and involves careful consideration of various factors, a detail often overlooked by many. At our company, we prioritize adherence to packing standards, especially when it comes to exporting products. Each member of our team is well-versed in the specific needs of our customers, ensuring that their products are packed with utmost care and attention. We believe that proper packing is not just a process but a commitment to safeguarding our customers' satisfaction and the integrity of their products throughout the shipping process.

Customer satisfaction is our top priority, which is why we strictly adhere to packing guidelines.